How New Bearing Materials Improve Handpiece Performance

2025-11-24

Why Modern Clinics and Distributors Should Care

Dental handpiece technology continues to advance, and one of the most impactful improvements in recent years comes from new bearing materials. Bearings directly influence how a handpiece runs—its speed, noise level, durability, and overall clinical comfort. With modern dentistry demanding higher precision and reliability, upgrading to improved bearing technologies has become essential for both clinics and distributors.

Below, we explore how new bearing materials enhance handpiece performance and why they matter.

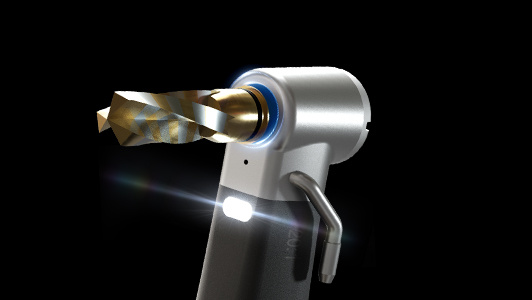

1. Enhanced Durability Through Ceramic and Hybrid Bearings

Traditional stainless-steel bearings have served the industry for decades, but newer materials—especially ceramic bearings and hybrid ceramic bearings—offer significantly better performance.

Key durability advantages:

Higher resistance to heat generated during high-speed rotation

Less wear due to smoother surface hardness

Longer lifespan even under heavy daily use

Reduced oxidation and corrosion

This means fewer cartridge failures, fewer replacements, and lower maintenance costs for clinics.

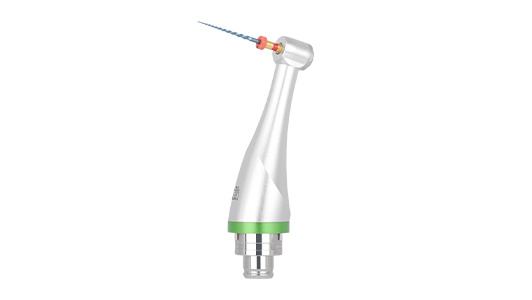

2. Improved Speed Stability and Smoother Rotation

New bearing materials minimize vibration and friction inside the turbine, allowing the handpiece to maintain high rotational speed more consistently.

Benefits of upgraded bearing materials:

Stable speed at 300,000–420,000 RPM

More accurate cutting and preparation

Better control for delicate treatments

Less interruption due to performance fluctuations

For dentists, this translates to smoother procedures and enhanced clinical precision.

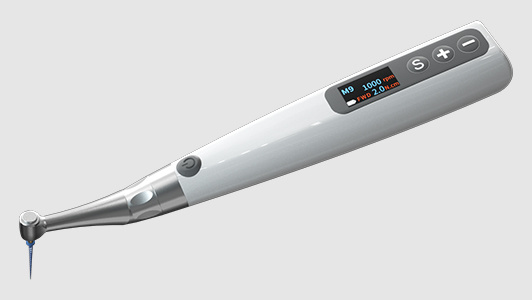

3. Lower Noise Levels for Better Patient and Dentist Comfort

Modern ceramic-based bearings generate far less friction than metal bearings. This results in:

Noticeably reduced noise during operation

Less vibration transmitted to the dentist’s hand

A more comfortable experience for anxious patients

A quieter, smoother handpiece helps create a calmer clinical environment—something many clinics now use as a selling point.

4. Better Heat Resistance and Longer Continuous Operation

Because ceramic materials can withstand higher temperatures, handpieces equipped with these bearings perform better during extended procedures.

Heat-resistance advantages:

Lower risk of overheating

Longer continuous operation times

Reduced damage to internal components

More reliable sterilization cycles

Clinics benefit from higher productivity and fewer interruptions.

5. Reduced Maintenance Requirements

New bearing technologies allow handpieces to run efficiently with less lubricant and reduced internal wear.

This leads to:

Longer intervals between servicing

Lower maintenance costs

Extended cartridge lifespan

Better performance even with frequent sterilization

For distributors, offering handpieces with high-end bearings becomes a key selling point—making it easier to attract clinics that prioritize long-term value.

Conclusion

The evolution of bearing materials has significantly improved the overall performance of dental handpieces. From enhanced durability and speed stability to lower noise levels and reduced maintenance needs, modern bearings contribute directly to better clinical outcomes.

Distributors and clinics that adopt advanced bearing technology gain clear advantages: fewer repairs, smoother operation, and improved patient comfort. As the industry continues to move toward high-precision and high-efficiency dentistry, choosing handpieces built with next-generation bearings is no longer optional—it is essential.

Previous:

Related News

Contact Us

Email:

info@koungsundental.com

Hotline:

+86-0757-81011906

Company Address:

4th floor, B elevator, Building F3, New Light Source Industrial Base, Nanhai District, Foshan City, Guangdong Province

Get in touch

Are you interested in our products or services? Contact us immediately, our experts will provide you with professional services!

*Please leave your specific personal information, and we will have a product consultant contact you later

Address

4th floor,B Elevator,Building F3,New Light Source Industrial Base,Nanhai District,Foshan City,Guangdong Province,China