How to Identify Early Signs of Handpiece Wear or Damage

2025-11-22

Dental handpieces are among the most frequently used instruments in any clinic, making them highly vulnerable to wear and performance decline over time. Identifying early signs of handpiece wear or damage not only prevents unexpected breakdowns but also protects treatment quality, patient comfort, and long-term equipment investment.

A proactive approach allows dental teams to address issues before they compromise safety or efficiency. Below are the key indicators every clinic should monitor to ensure optimal handpiece performance.

1. Increased Noise or Vibration

One of the earliest warnings of internal wear is unusual noise or vibration during operation.

Common causes include:

Worn bearings

Imbalanced turbine

Loose cartridge components

A smooth handpiece should operate quietly. When noise increases, it’s time for inspection or servicing before irreversible damage occurs.

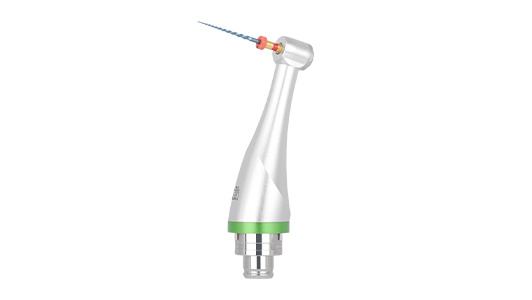

2. Reduced Cutting Power

If a handpiece no longer cuts as efficiently as before, performance loss may indicate:

Bearing deterioration

Turbine fatigue

Air leakage or blockage

Decreased torque slows procedures and affects precision, signaling that internal parts may require repair or replacement.

3. Overheating During Use

A properly functioning handpiece should remain cool. Overheating may suggest:

Dry or insufficient lubrication

Damaged bearings causing friction

Blocked air pathways

Ignoring heat buildup can lead to patient discomfort and permanent turbine damage.

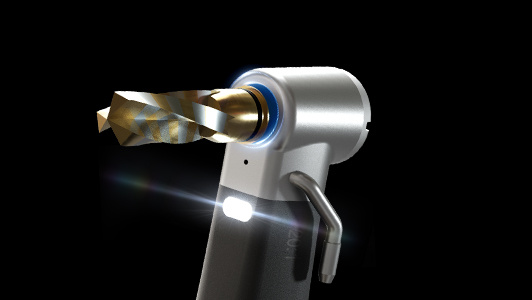

4. Irregular Bur Movement or Runout

Signs of bur instability include:

Bur wobbling

Difficulty inserting or removing burs

Slight misalignment during rotation

These issues often come from spindle wear, damaged chuck mechanisms, or a fatigued cartridge. Early detection prevents further internal damage.

5. Air or Water Spray Inconsistencies

A healthy handpiece delivers smooth water spray and consistent airflow. Irregular patterns indicate potential problems such as:

Blocked water lines

O-ring wear

Internal corrosion

Proper spray is crucial for cooling and visibility during procedures, making this an important performance indicator.

6. Longer Procedure Times

If dentists notice increasing treatment time, the handpiece may no longer be working at its intended efficiency.

Internal wear commonly affects:

RPM stability

Torque output

Bur retention strength

This operational decline is often subtle but important to monitor.

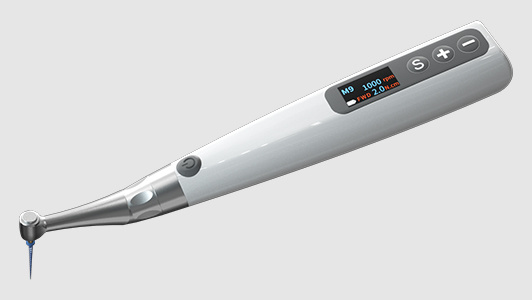

7. Frequent Need for Lubrication or Maintenance

When a handpiece suddenly requires more frequent lubrication or attention, it may mean internal components are approaching end of life.

Signs include:

Lubrication leakages

Oil dripping after autoclaving

Unusual resistance during rotation

Such indicators often precede bearing or turbine failure.

Why Early Detection Matters

Identifying wear early helps clinics:

Reduce repair costs

Extend handpiece lifespan

Maintain treatment accuracy

Ensure patient comfort and safety

Prevent sudden downtime during operations

Routine inspection and timely cartridge or bearing replacement are essential to protecting your investment.

Previous:

Related News

Contact Us

Email:

info@koungsundental.com

Hotline:

+86-0757-81011906

Company Address:

4th floor, B elevator, Building F3, New Light Source Industrial Base, Nanhai District, Foshan City, Guangdong Province

Get in touch

Are you interested in our products or services? Contact us immediately, our experts will provide you with professional services!

*Please leave your specific personal information, and we will have a product consultant contact you later

Address

4th floor,B Elevator,Building F3,New Light Source Industrial Base,Nanhai District,Foshan City,Guangdong Province,China