Why Should Dental Clinics Consider Electric Micromotors Instead of Air-Driven Models?

2025-09-25

In modern dentistry, the shift from air-driven systems to electric micromotors is gaining momentum. But what makes electric micromotors compelling for dental clinics? Below we explore the key benefits, use cases, and considerations — and introduce a high-quality option from KOUGSUN.

1. What is the difference between electric micromotors and air-driven handpieces?

Air-driven systems (traditional): Use compressed air to spin turbines in contra-angle handpieces. The speed and torque depend on air pressure and turbine efficiency.

Electric micromotors: Use a motor (often brushless) under electronic control, with a contra angle or handpiece head attached. The speed, torque, and control come from electrical input, not air pressure.

This shift in energy source brings significant differences in performance and control.

2. What are the clinical advantages of electric micromotors?

a) Consistent torque and power under load

When cutting harder materials (ceramic, metals, dense dentin), air turbines may slow down or lose torque. Electric micromotors maintain stable speed under load, reducing stalling and improving cutting efficiency.

b) Better speed control and reversibility

Electric systems often allow precise speed adjustment, forward/reverse direction, and micromotor control via foot pedals or control boxes. This is especially useful in endodontics, prosthodontics, implant surgery, and polishing.

c) Less noise and vibration

Electric motors tend to run more quietly with smoother rotational behavior. Reduced vibration improves handling comfort for the clinician and enhances patient experience.

d) Lower heat generation and better thermal management

Because the motor is controlled and not relying on compressed air, electric systems often produce less excess heat. With proper cooling (water spray, internal channels), they protect tissues better.

e) Better integration with digital workflows

Electric micromotors can integrate with CAD/CAM, implant systems, or digital prosthetic workflows. Their electronic control makes automation and data feedback possible.

3. What are the practical benefits for a dental practice?

Versatility across procedures: Use the same motor for high-, low-speed, polishing, implant drilling, orthodontic appliance removal, etc.

Efficiency and predictability: Because performance is more predictable under different loads, clinicians save time and reduce risk of errors.

Longer device life and lower maintenance: Fewer mechanical losses and less wear from fluctuating airflow pressures mean components last longer.

Patient comfort and perception: Quieter, smoother operations enhance patient comfort and perceived professionalism.

4. What should clinics and distributors look for when selecting an electric micromotor?

| Feature | Why It Matters |

|---|---|

| Brushless motor / high torque | More efficient, longer life, better performance |

| Speed range & control (e.g. 1,000–40,000 rpm or more) | Ability to handle everything from endo to polishing |

| Internal water spray / cooling system | Prevent overheating and protect tissues |

| Sterilizable housing | Must withstand autoclave / high temperature & pressure |

| Compact size & light weight | Ergonomics matter for long use |

| LED light / illumination | Improves visibility during procedures |

| Vendor support, parts availability & compatibility | To maintain uptime and user confidence |

| Certifications (CE, ISO, FDA, etc.) | For safety, quality, and regulatory compliance |

5. Use Cases: When electric micromotors excel

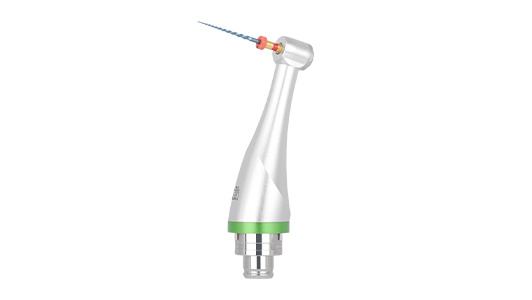

Endodontics: Precise low-speed control and reversal help in files and NiTi rotary systems.

Prosthetics & polishing: Smooth torque at lower speeds is ideal for finishing, adjusting, smoothing and polishing restorations.

Implantology / surgical procedures: Some systems support surgical drills with torque and speed control.

Orthodontics / lab use: Removal of bonds, finishing, adjusting appliances.

Multi-purpose clinics: One motor, multiple handpieces or attachments reduces device count.

Product Showcase: Electric Micromotors from KOUGSUN

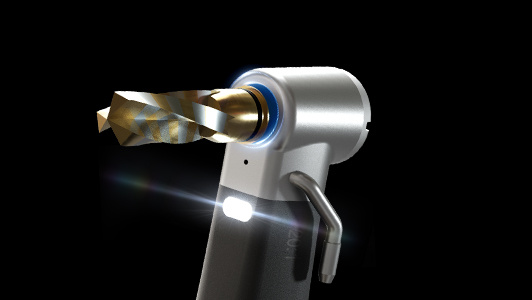

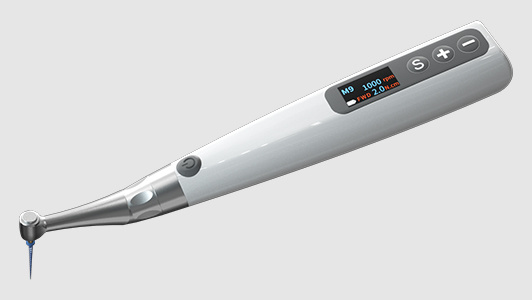

KOUGSUN’s Micro Electric Motor E130 (and related micromotor line) is an excellent example of a premium electric micromotor solution. Key features include:

Brushless motor with internal water spray for stable performance and cooling.

Speed range: 1,000 to 40,000 rpm — offering flexibility across many dental procedures.

Maximum torque up to 2.5 Ncm — suitable for many clinical tasks.

LED illumination built in, improving visibility during procedures.

Sterilizable design: supports high-temperature and high-pressure sterilization.

Compact form factor (≈ Ø21 mm × 42 mm) and broad power compatibility (100-240 VAC).

To learn full specs or place an inquiry: KOUGSUN Micro Electric Motor / Micromotors

This micromotor is designed to help clinics upgrade their performance and transition smoothly from traditional air systems.

Conclusion

While air-driven systems have been a mainstay for decades, electric micromotors present compelling advantages in torque stability, control, noise, durability, and integration with digital dentistry. For dental clinics aiming to deliver better outcomes, greater efficiency, and a more professional patient experience, electric micromotors are a strategic upgrade.

If you’re ready to explore high-performance electric micromotor solutions, be sure to check out KOUGSUN’s micromotor offerings:

KOUGSUN Micromotors / Micro Electric Motor E130

Previous:

Related News

Contact Us

Email:

info@koungsundental.com

Hotline:

+86-0757-81011906

Company Address:

4th floor, B elevator, Building F3, New Light Source Industrial Base, Nanhai District, Foshan City, Guangdong Province

Get in touch

Are you interested in our products or services? Contact us immediately, our experts will provide you with professional services!

*Please leave your specific personal information, and we will have a product consultant contact you later

Address

4th floor,B Elevator,Building F3,New Light Source Industrial Base,Nanhai District,Foshan City,Guangdong Province,China