How Important Are Bearings and Cartridges in Handpiece Maintenance?

2025-09-23

In dental practice, high-quality handpieces are essential—but their performance and lifespan depend heavily on internal parts, especially bearings and cartridges. For dentists and dental equipment distributors, understanding how these components work and when to replace them can make a major difference in clinical outcomes, cost efficiencies, and customer satisfaction.

What are bearings and cartridges, and what roles do they play?

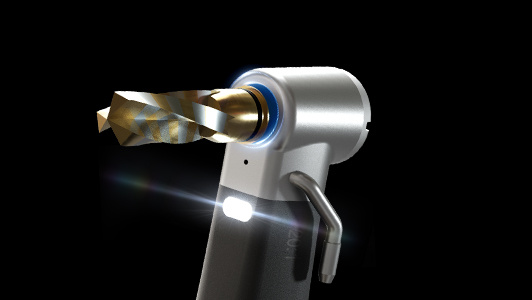

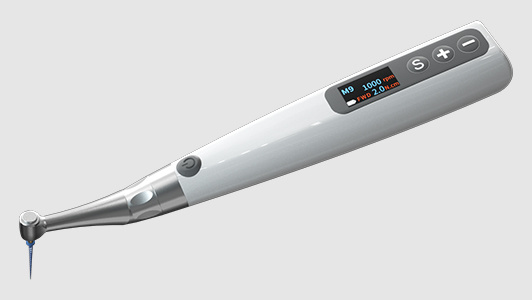

Bearings: These are precision components (often ceramic or hybrid ceramic + metal) inside the turbine and rotor of a handpiece. They enable smooth, balanced rotation at very high RPMs. Good bearings reduce vibration, noise, and heat.

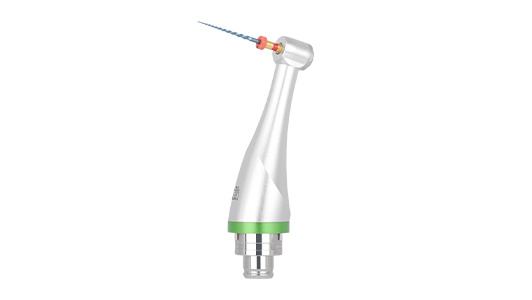

Cartridges (or turbine cartridges): A cartridge is the assembly that houses the turbine, rotor, blades, and housing that spins. It’s what converts air or electric power into the cutting motion. The cartridge must be precisely engineered; its balance and alignment directly affect cutting efficiency and durability.

Why are they critical for handpiece performance?

Smooth operation and patient comfort

Worn bearings or misaligned cartridges cause wobbling, uneven motion, vibration. That leads to poor cutting, discomfort for the patient, and fatigue for the operator.

Heat control and safety

Friction from bad bearings or poor cartridge condition generates excess heat, which can damage tooth structure or even cause pulp irritation. Adequate cooling helps, but it's less effective when internal parts are degraded.

Efficiency and precision

When bearings are high-quality and cartridges are well-balanced, rotational speed is consistent, cutting is precise, margins are clean. This is crucial for restorative work—crowns, inlays, root-canal access, etc.

Durability & total cost of ownership (TCO)

Replacing a whole handpiece is expensive. But maintaining internal parts—keeping bearings smooth, replacing weak cartridges—extends the useful life. For distributors, offering spare parts and service boosts trust and recurring business.

When to inspect or replace bearings & cartridges

| Sign | What It Indicates | Recommended Action |

|---|---|---|

| Loud noise / grinding sound | Bearings are worn | Inspect bearings; replace promptly |

| Decreased RPM or cutting efficiency | Cartridge or turbine blades compromised | Replace cartridge or turbine assembly |

| Increased vibration or wobble | Bearing looseness or poor cartridge alignment | Service or replace parts |

| Overheating / burning smell | Excess friction | Maintenance plus replacement of worn parts |

| Fluid/water spray reduced or uneven | Internal channels or cartridge damage | Clean & check cartridge; possibly replace |

What qualities to look for in high-quality bearings & cartridges

Material: Ceramic or hybrid bearings tend to last longer and resist wear better than plain metal bearings.

Precision manufacturing / balance: Small tolerances. Turbine balanced so rotor doesn’t wobble at high speed.

Brand compatibility: Some handpieces have specific cartridge / turbine types. Make sure spare parts are correct.

Ease of replacement: Cartridges that are modular and easy to swap reduce downtime.

Certification & quality control: ISO, CE, FDA etc., for both bearings and cartridges. This ensures consistent manufacturing and safety.

Impact for Distributors & Clinics

Clinics that invest in proper maintenance see fewer complaints, fewer instrument failures, less risk of cross-contamination and better patient satisfaction.

Distributors who stock reliable bearings & cartridges, offer guidance on maintenance schedules, and supply replacements quickly gain customer loyalty.

Spare parts can form a steady revenue stream. Clinics always need replacement cartridges and bearings over time.

Product Spotlight: Cartridge Set from KOUGSUN

To illustrate what high-quality spare parts look like, consider, a cartridge set offered by KOUGSUN. Key features include:

Designed for precision fit and alignment, to restore handpiece performance. (Check specs on the product page: Cartridge Set)

Manufactured to high standards, ensuring bearings are balanced, noise and vibration are minimized.

Compatible with various handpiece models, facilitating easy swap-outs and minimizing downtime.

Optimized materials and craftsmanship so that clinics can extend handpiece lifespan and maintain consistent cutting efficiency.

Conclusion

Bearings and cartridges are not just “internal parts” — they are critical components that determine how well a handpiece performs, how comfortable the patient experience is, and how much long-term cost and effort maintenance will incur. For both dentists and distributors, investing in quality bearings and cartridges, and replacing them at the right time, is essential.

Related News

Contact Us

Email:

info@koungsundental.com

Hotline:

+86-0757-81011906

Company Address:

4th floor, B elevator, Building F3, New Light Source Industrial Base, Nanhai District, Foshan City, Guangdong Province

Get in touch

Are you interested in our products or services? Contact us immediately, our experts will provide you with professional services!

*Please leave your specific personal information, and we will have a product consultant contact you later

Address

4th floor,B Elevator,Building F3,New Light Source Industrial Base,Nanhai District,Foshan City,Guangdong Province,China