How a Structured Technical Training System Reduces Service Costs and Strengthens Distributor Competitiveness

2026-02-12

Introduction: Why Technical Training Is No Longer Optional

In today’s competitive dental equipment market, distributors are expected to provide more than product supply. Clinics increasingly demand fast technical support, accurate troubleshooting, and minimal downtime. Without a structured technical training system, distributors face higher after-sales costs, repeated product returns, and weakened customer trust.

A well-designed technical training system for dental handpieces helps distributors reduce service risks, improve maintenance efficiency, and build long-term clinic loyalty.

1. The Hidden Cost of Inadequate Technical Knowledge

Many after-sales issues do not originate from product defects but from:

Incorrect lubrication procedures

Improper sterilization cycles

Cartridge misinstallation

Overuse without scheduled maintenance

Wrong air pressure settings

Without proper training, distributors often:

Accept unnecessary warranty returns

Replace entire handpieces instead of components

Bear high logistics and repair costs

Damage brand reputation

Technical training directly reduces these avoidable expenses.

2. Core Elements of a Professional Training System

An effective dental handpiece training program should include:

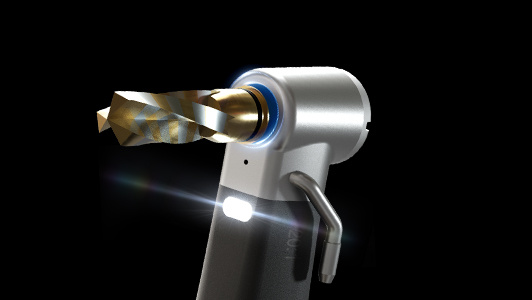

A. Product Structure Understanding

Handpiece head structure

Bearings and cartridge design

Spray system configuration

Air-driven vs electric systems

Understanding internal components allows distributors to diagnose issues quickly.

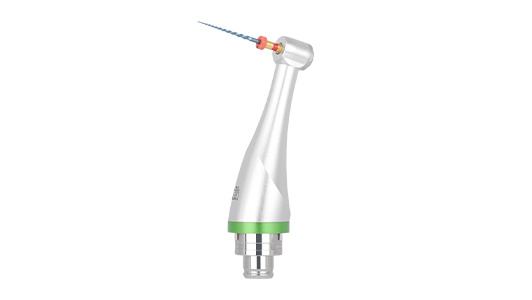

B. Standard Maintenance Procedures

Correct lubrication method and frequency

Autoclave best practices

Daily, weekly, and monthly maintenance guidelines

Cartridge replacement standards

Clear maintenance guidelines reduce premature wear and warranty claims.

C. Troubleshooting Protocols

Training should cover common issues such as:

Noise increase

Vibration problems

Reduced torque

Water spray blockage

RPM instability

With structured troubleshooting steps, distributors can solve most issues locally without returning products to the factory.

3. How Training Reduces After-Sales Costs

A structured training system improves:

✔ First-Time Fix Rate

Technicians solve issues correctly on the first attempt, minimizing repeat service.

✔ Spare Parts Optimization

Distributors learn when to replace:

Bearings

Cartridges

O-rings

Spray kits

Instead of replacing full units, targeted part replacement significantly lowers costs.

✔ Warranty Control

Accurate diagnostics help identify misuse versus manufacturing defects, protecting profit margins.

4. Training as a Competitive Advantage

Technical capability differentiates distributors in saturated markets.

Clinics prefer suppliers who can:

Provide on-site maintenance guidance

Offer technical workshops

Train clinic staff on handpiece care

Deliver faster repair turnaround

A distributor with a professional technical support system gains:

Higher customer retention

Stronger clinic loyalty

Increased repeat orders

Greater credibility in tenders

Training transforms a distributor from a reseller into a technical partner.

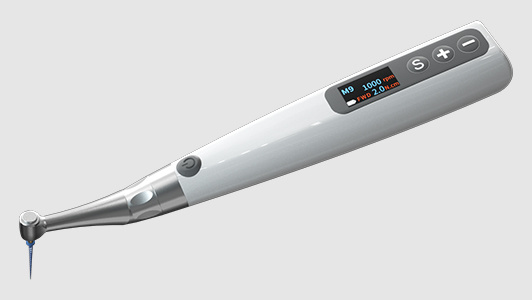

5. Digital Training Tools and Modern Support Models

In 2026 and beyond, advanced manufacturers provide:

Video-based repair tutorials

Online technical documentation

Exploded component diagrams

Remote troubleshooting support

Structured spare parts manuals

These resources shorten learning curves and standardize service quality across regions.

Distributors who leverage factory training systems operate more efficiently and scale faster.

6. Building Long-Term Market Stability Through Knowledge

A product can be copied.

Pricing can be matched.

But a strong technical service system is difficult to replicate.

Distributors that invest in structured training build:

Sustainable profit margins

Lower operational risk

Stronger brand positioning

Long-term clinic trust

Technical knowledge is no longer an expense — it is a strategic asset.

Partner with a Manufacturer That Supports Your Technical Growth

A reliable dental handpiece manufacturer should provide not only quality products but also:

Comprehensive technical training

Clear maintenance documentation

Spare parts system guidance

Long-term service collaboration

KOUNGSUN Dental supports distributors with structured product knowledge materials, spare parts supply systems, and technical assistance designed to help partners reduce after-sales costs and strengthen their competitive advantage.

Learn more about our products and partnership opportunities:

👉 https://www.koungsundental.com/products_list/2.html

Previous:

Related News

Contact Us

Email:

info@koungsundental.com

Hotline:

+86-0757-81011906

Company Address:

4th floor, B elevator, Building F3, New Light Source Industrial Base, Nanhai District, Foshan City, Guangdong Province

Get in touch

Are you interested in our products or services? Contact us immediately, our experts will provide you with professional services!

*Please leave your specific personal information, and we will have a product consultant contact you later

Address

4th floor,B Elevator,Building F3,New Light Source Industrial Base,Nanhai District,Foshan City,Guangdong Province,China