Distributor Service System Guide

2026-02-11

How a Spare Parts Strategy Increases Profitability and Customer Retention

In the dental equipment industry, many distributors focus primarily on unit sales. However, long-term profitability is rarely built on handpiece sales alone. The real engine of sustainable growth lies in a well-structured spare parts and after-sales system.

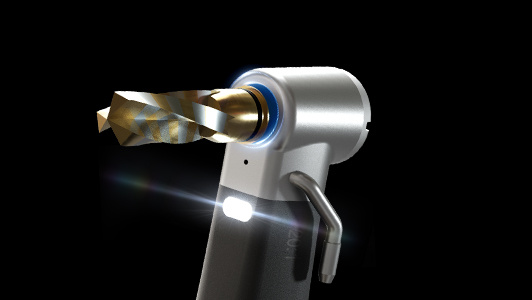

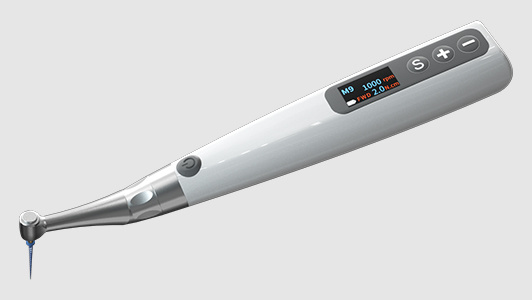

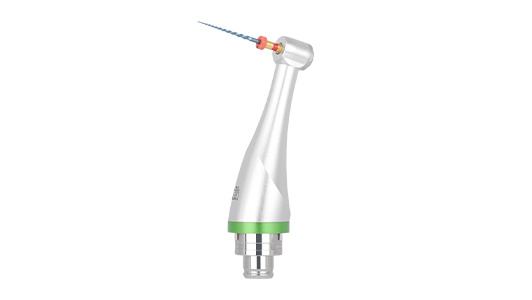

For high-speed and low-speed dental handpieces, components such as bearings, cartridges, and spray kits are consumable and service-critical parts. Distributors who manage spare parts efficiently gain stronger customer loyalty, faster service turnaround, and more stable recurring revenue.

This article explains:

Why spare parts define long-term distributor profitability

How to structure a strategic spare parts inventory

How spare parts increase customer retention

How manufacturers can support efficient after-sales workflows

1. Why Spare Parts Determine Long-Term Profit

One-Time Equipment Margin vs. Recurring Service Revenue

Complete handpiece sales are often:

Highly price-competitive

Sensitive to market fluctuations

Easily compared across brands

Once the initial sale is completed, distributors without service capability risk losing customers to third-party repair providers.

In contrast, spare parts and maintenance services offer:

Recurring revenue

Higher average margins

Strong technical dependency

Long-term customer relationships

In other words:

Equipment sales bring customers. Spare parts build sustainable profit.

2. Designing a Strategic Spare Parts Inventory

Many distributors face challenges such as:

Long repair turnaround times

Out-of-stock components

Excess capital tied up in slow-moving inventory

A structured three-tier inventory model can solve these issues.

Tier 1: High-Frequency Consumables (Must-Stock Items)

Examples:

Front and rear bearings

Spray kits

O-rings and seals

Recommendation:

Maintain inventory sufficient for 1–2 months of average repair demand.

Goal:

Complete routine repairs within 24–48 hours.

Tier 2: Medium-Frequency Structural Components

Examples:

Cartridges

Push-button systems

Rotor assemblies

Recommendation:

Replenish quarterly based on service volume.

Goal:

Avoid overseas delays for common structural repairs.

Tier 3: Low-Frequency Parts (On-Demand Supply)

Examples:

Housing components

Special internal mechanisms

Strategy:

Establish fast-response supply coordination with the manufacturer.

3. How Spare Parts Increase Customer Retention

Faster Repairs Build Trust

For dental clinics, equipment downtime directly impacts revenue. Distributors who can provide:

24–48 hour repair turnaround

Reliable, high-precision replacement parts

Transparent service records

significantly strengthen customer loyalty.

When service becomes reliable and predictable, customers are far less likely to switch suppliers.

Quality Spare Parts Reduce Long-Term Risk

Non-original or low-quality components often cause:

Increased vibration

Unstable power output

Shortened service life

Higher failure rates

Using precision-manufactured spare parts ensures stable performance and protects the clinic’s investment.

Manufacturers with strong precision machining foundations, such as KOUNGSUN Dental, focus on component consistency, durability, and compatibility. This level of quality control helps distributors reduce after-sales complaints and lower long-term service costs.

More information about precision dental handpieces and components can be found at:

https://www.koungsundental.com

For distributors, consistent product structure means:

Fewer service risks and stronger brand credibility.

4. Building an Efficient Manufacturer–Distributor Support System

A professional manufacturing partner should provide:

Standardized Spare Parts Lists

Clear exploded diagrams and model-matching references.

Technical Training Resources

Maintenance videos

Disassembly instructions

Troubleshooting guides

Flexible Replenishment Support

Small-batch orders

Separate spare parts shipments

Emergency supply options

Quality Traceability

Ensuring batch consistency and manufacturing precision.

A strong manufacturer partnership transforms spare parts management from a reactive task into a strategic advantage.

5. Example Profit Model (Distributor Perspective)

Assume a distributor sells 50 handpieces per month.

If 20% enter maintenance cycles within one year, and the average service margin per repair ranges between $30–80, this creates a steady and scalable after-sales revenue stream.

More importantly:

Customers who rely on your service system are more likely to repurchase equipment from you over the next 3–5 years.

This recurring cycle significantly exceeds the profit of one-time equipment sales.

6. The Strategic Role of Spare Parts

Spare parts are not merely after-sales accessories. They represent:

Customer control

Service authority

Cash flow stability

Market differentiation

Mature distributors do not only sell products — they provide reliable technical support systems.

In today’s competitive dental market, upgrading from product seller to service-oriented partner is essential. A well-designed spare parts strategy is the foundation of that transformation.

Related News

Contact Us

Email:

info@koungsundental.com

Hotline:

+86-0757-81011906

Company Address:

4th floor, B elevator, Building F3, New Light Source Industrial Base, Nanhai District, Foshan City, Guangdong Province

Get in touch

Are you interested in our products or services? Contact us immediately, our experts will provide you with professional services!

*Please leave your specific personal information, and we will have a product consultant contact you later

Address

4th floor,B Elevator,Building F3,New Light Source Industrial Base,Nanhai District,Foshan City,Guangdong Province,China